News & Blogs

"Best Construction Materials for Building Homes in Nepal: Cement, Sand, and Aggregate Selection"

Civil Solution Pvt.Ltd recognize that the choice of construction materials significantly impacts the quality, strength, and longevity of your home. In Nepal, where geographical diversity and varying climates present unique challenges, selecting the appropriate materials is crucial for ensuring durability and structural integrity. Below, we provide a detailed guide to help you choose the best cement, sand, and aggregates for building homes in Nepal.

1. Cement

Cement serves as the core binding agent in concrete and mortar. The selection of cement is vital for achieving the required strength and durability in your structure.

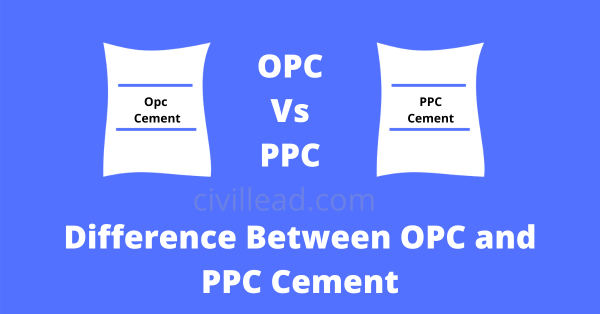

- Ordinary Portland Cement (OPC):

OPC is the most commonly used cement for general construction in Nepal. Available in grades 43 and 53, it offers reliable strength and is cost-effective for most residential applications. OPC grade 43 is generally sufficient for typical home construction needs.

- Pozzolanic Portland Cement (PPC):

PPC is a blend of OPC and pozzolanic materials like fly ash. This type of cement is ideal for areas exposed to moisture or aggressive environmental conditions. PPC offers enhanced durability, improved resistance to cracking, and increased strength, making it well-suited for homes in regions with high humidity or rainfall.

- Sulphate Resisting Cement (SRC):

In locations where the soil or groundwater contains high levels of sulphates, SRC is the preferred choice. This cement type resists sulphate-induced corrosion, helping to maintain the structural integrity of your home over time.

2. Sand

Sand is a fundamental component in both mortar and concrete. The quality of sand affects the overall strength and workability of the final product. The most common types of sand used in Nepal include:

- River Sand:

River sand is traditionally used due to its smooth texture, cleanliness, and suitability for both concrete and plaster. When sourced from clean and uncontaminated riverbeds, it ensures excellent workability and helps produce strong, durable concrete.

- Crushed Sand (Manufactured Sand):

Crushed sand is gaining popularity due to increasing restrictions on river sand extraction. While it has sharp angular particles that improve bonding strength with cement, it may require more water to achieve the desired workability. It is important to ensure that crushed sand is well-graded and free from impurities.

3. Aggregates

Aggregates play a key role in determining the strength, durability, and texture of concrete. They are categorized into coarse and fine aggregates.

- Coarse Aggregates:

For structural applications such as foundations, beams, and columns, coarse aggregates are essential. Crushed stone or gravel with a size range of 10 mm to 20 mm is commonly used for reinforced concrete. Crushed stone is generally preferred due to its rough texture, which enhances the bond with cement and results in stronger concrete.

- Fine Aggregates:

Fine aggregates, like sand, are used in mortar for plastering, masonry, and tile installation. The particle size of fine aggregates should fall between 0.075 mm and 4.75 mm. It is essential to use clean, well-graded sand to avoid weakening the mortar mix.

4. Water

The quality of water used in mixing concrete and mortar is critical. It is essential to use clean, potable water, as contaminated water can disrupt the hydration process of cement, leading to weak concrete. Avoid water with high levels of organic matter or salts, as it can adversely affect the concrete's strength and durability.

Key Considerations for Construction in Nepal

-

Climatic Conditions:

Nepal’s diverse climate, ranging from tropical to alpine, necessitates careful selection of materials. In areas with high humidity or heavy rainfall, PPC cement and moisture-resistant materials are recommended for better durability and structural stability. -

Durability and Structural Integrity:

Sourcing materials from reputable suppliers is crucial to ensuring the strength and longevity of your construction. This is especially important in seismic zones, as strong, well-constructed materials will help mitigate the risks posed by earthquakes and other environmental factors. -

Availability and Cost:

Material availability varies by region. While OPC and river sand are readily accessible in many areas, the increasing demand for crushed sand and other alternatives may affect cost and availability. Balancing cost with material quality is key to keeping your project within budget while ensuring the longevity of the structure. -

Environmental Responsibility:

As sustainable construction practices become more important, consider using eco-friendly materials such as PPC cement or recycled aggregates to reduce the environmental impact of your project. These materials not only improve the sustainability of your home but also contribute to long-term savings.

Conclusion

Selecting the right materials for construction is fundamental to ensuring the quality, safety, and durability of your home. By choosing high-quality cement, aggregates, and sand, and taking into account the local environmental conditions, you can build a home that will stand the test of time. We are committed to using only the best materials and delivering projects that meet the highest standards of quality and safety.

For further guidance or to discuss your construction needs, contact Civil Solution Pvt.Ltd today. Let us help you build your dream home with the right materials for a lasting, resilient structure.

-1735451723.jpg)